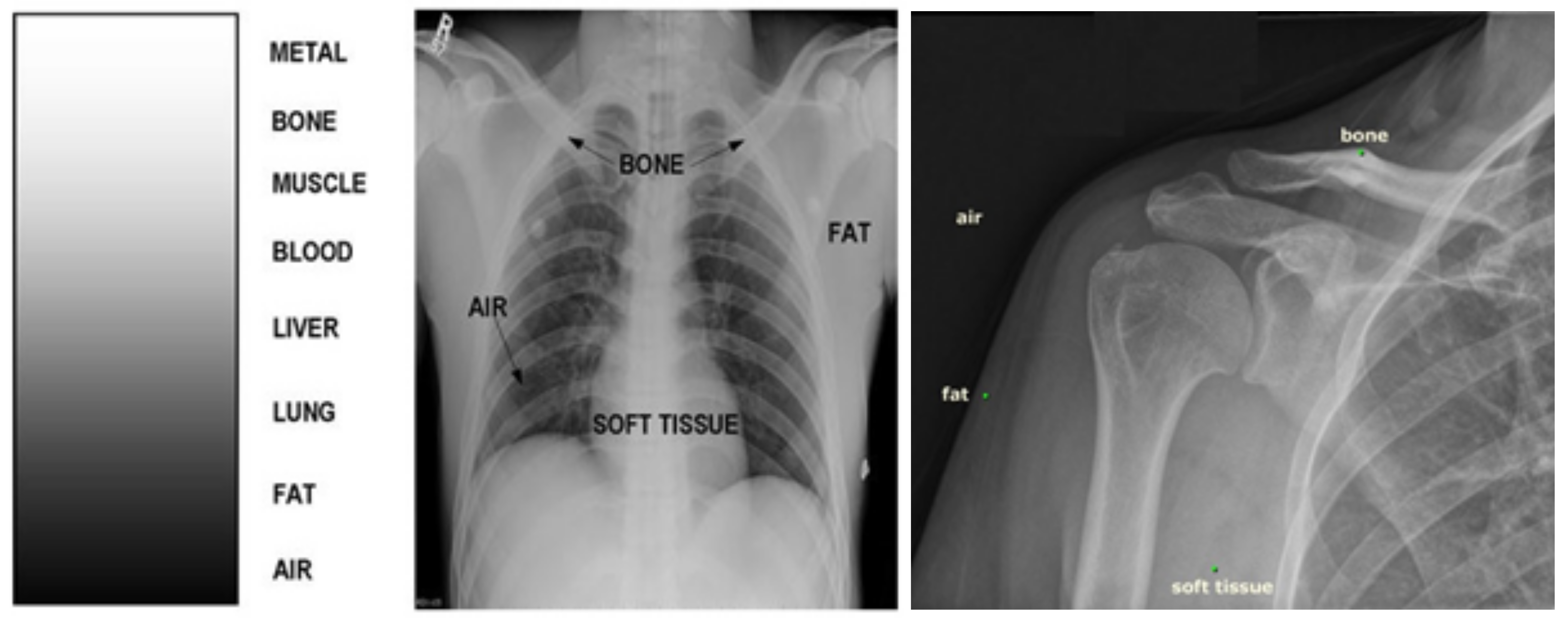

In the X-Ray radiograph, the information is in the form of grey color densities from clear transparent to black. When the human body is exposed to X-ray radiation, the density is captured on the X-ray Radiograph based on the absorption capacities of human body parts.

Most transparent being the metallic parts and the darkest being the Air.

This information can be visualized from the X-ray radiograph, When the X-ray radiograph viewer surface has good illumination uniformity, good diffusion, and is glare-free.

How is the uniform illumination achieved in the X-Ray Viewer?

The light source comprises several LEDs which are arranged in a particular pattern behind the diffuser sheet. To get uniformity all LEDs should be alike. This is ensured by testing and grouping all similar LEDs. This process is also known as Binning. Generally, A-grade LED manufacturers like Nichia, Cree, Avago, etc. supply these binned LEDs. The production yield of these binned LEDs is lower as compared to un-binned LEDs. Hence Binned LEDs are costly as compared to un-binned LEDs. Even the performance degradation of few LEDs introduces dark spots which give misleading information.

The second level of Binning is done at the manufacturing process of the Viewer, which involves sophisticated instrumentation like Photo Spectrometer, Illumination meters, Integrating spheres, intensity adapters, etc. Which are costly, which impacts the manufacturing cost.

All the Xray Viewers manufactured at Efftronics Systems use the binned LEDs manufactured by Nichia, Osram with strict internal quality checks where 100% of the LEDs are tested before manufacturing. All the X-ray viewers are aged for 168 hours at 60 deg centigrade to detect any early failures before being delivered to the customers.

How is good Diffusion achieved in the X-Ray Viewer?

Diffusion is the optical property of the material to scatter the light across its surface, which makes the surface to glow with light. Plastic Materials likes Polycarbonate and Acrylic has good diffusion properties.

These diffusers have a property of turning yellow when they get exposed to light radiation, over a period. This can be prevented by selecting the diffusor material having UV inhibitors. Another important parameter is the thickness of the sheet. Too thin sheet produces glare, too thick sheet makes the surface appear dim which requires more power to achieve target illumination.

Reputed companies like Sabic, Bayer, Plexiglas supplies the genuine material which comes with a ten-year warranty and are expensive as compared to Chinese counterparts which do have UV stabilizers.

The Xray viewers manufactured at Efftronics Systems use LEXAN Polycarbonate diffusion sheets manufactured by Sabic Innovative plastics. Each sheet is thoroughly scanned and graded for the cleanest surface without dust particles which get trapped internally at the time of sheet extrusion. We ensure that all the viewing surface is clear and free from any misleading dark dust spots.

Glare-Free and flicker-free

Glare is the loss of visual performance or discomfort produced by the intensity of light to which the eyes are adopted. In other words, too much light enters your eyes and interferes with your ability to manage it.

Hence when the viewer has glare, the radiologist can’t capture total and finer details which are very important for diagnosis. Glare can be reduced by proper intensity distribution and limiting the amount of light per unit area with certain maximum to minimum limits.

Flicker-free property is achieved by having ripple-free power supplies and with proper LED driver management. The power line filter components should be rated for longer life and higher temperature.

Another important feature is the safety of the equipment and reliability of equipment. Safety & reliability is achieved through the right design, right source of component, and right manufacturing process. We at Efftronics Systems Pvt Ltd have more than 20 years of experience in designing and developing Fail-Safe products in various domains and applications as per various international safety standards.

Whether to choose Backlit or Edge-Lit viewer

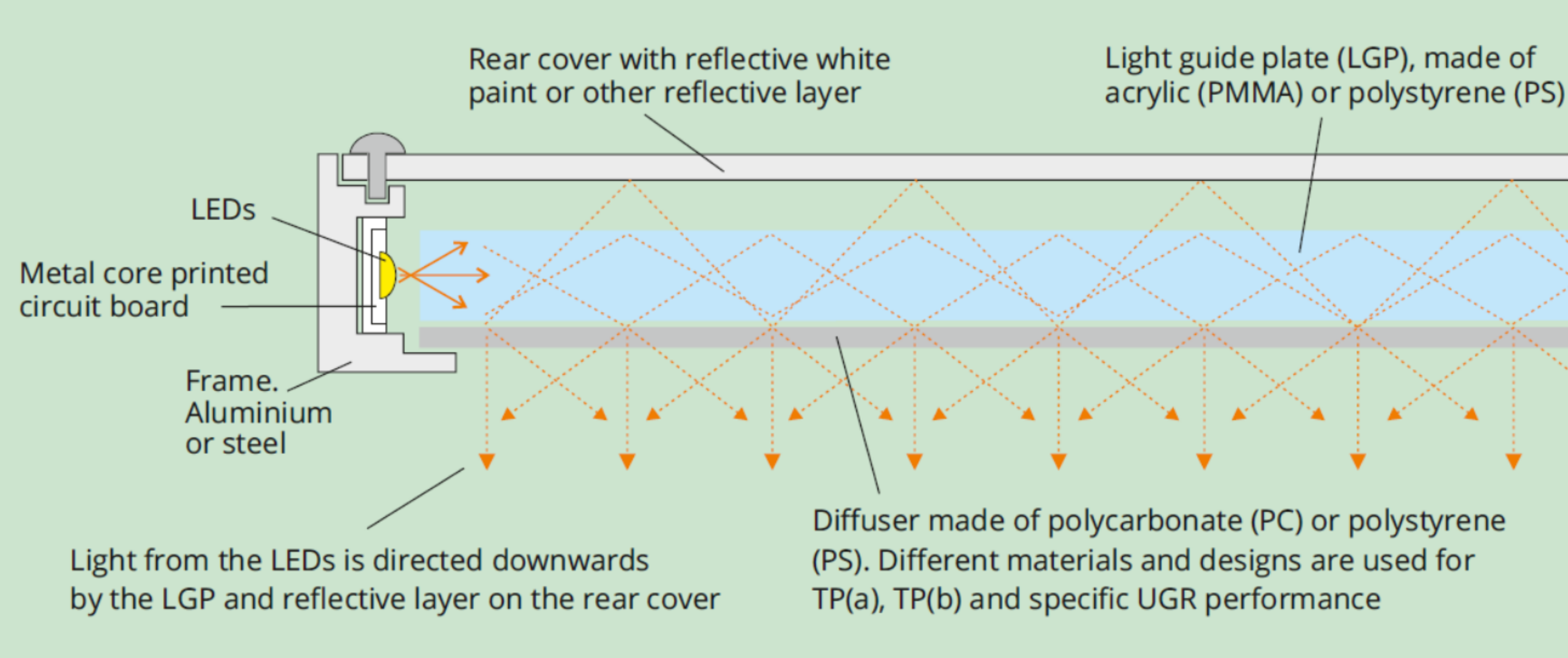

In Edge lit Technology the LEDs which comprise the light source, are placed on the edges of the diffuser plate know as Light Guide Plate (LGP) which diffuses the light across the surface of the Light guide plate.

Few LEDs are used, since LED’s placed around the edge generally, these viewers are slim in thickness. However good is the quality of the light guide plate, the center of the viewer will generally be dark as compared to the edges. Good quality light guide plate with stabilization is very expensive, low-cost LGP comes without stabilization and degrades fast, and causes dimming of illumination over a period. Secondly, since fewer LEDs are used any decrease in intensity impacts heavily on the uniformity hence the poor quality of visualization of the radiograph.

The only Advantage of these types of technology is that they are thinner which gives sleek look in appearance.

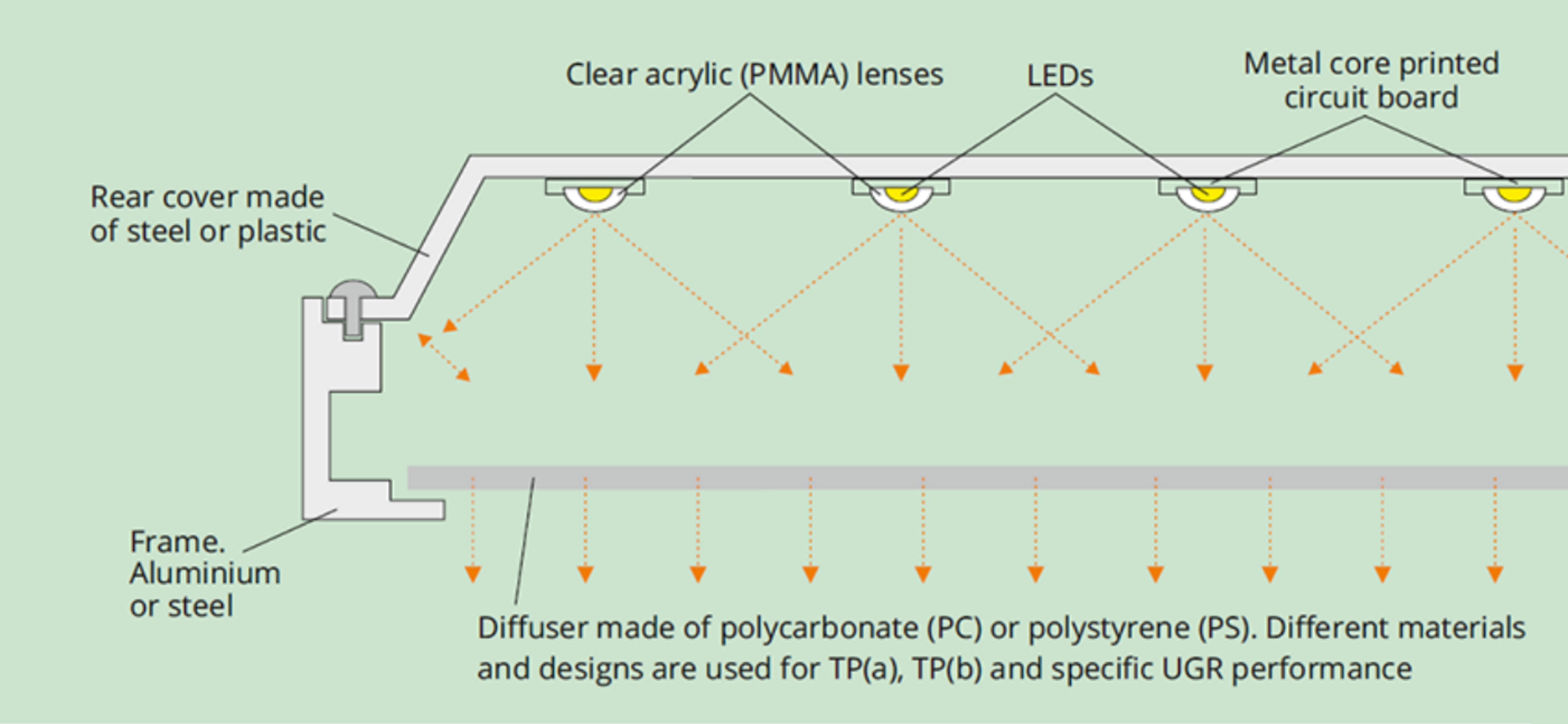

Back Lit Technology:

The LEDs are placed uniformly behind the diffuser sheet. More number of LEDs are used on compared to Edge Lit hence better Illumination with good uniformity and lesser impact in case of any performance degradation of LEDs.

Since the LEDs have become more efficient as compared to earlier parts. Thermal management of back lit has also become much easier and reliable. The only drawback incase back lit X-Ray viewer is that it is a bit thicker as compared to edge lit.

All the X ray viewers manufactured at Efftronics use the Back lit technology giving the best uniformity. All our X ray viewers have min/max intensity ratio greater than 0.6. All the X ray viewers are provided with smooth Dimming feature to suit the viewing convenience of different users.