“An ounce of prevention is worth a pound of cure.” ― Benjamin Franklin

Scourge of the past is to be stuck with old and conventional methods…

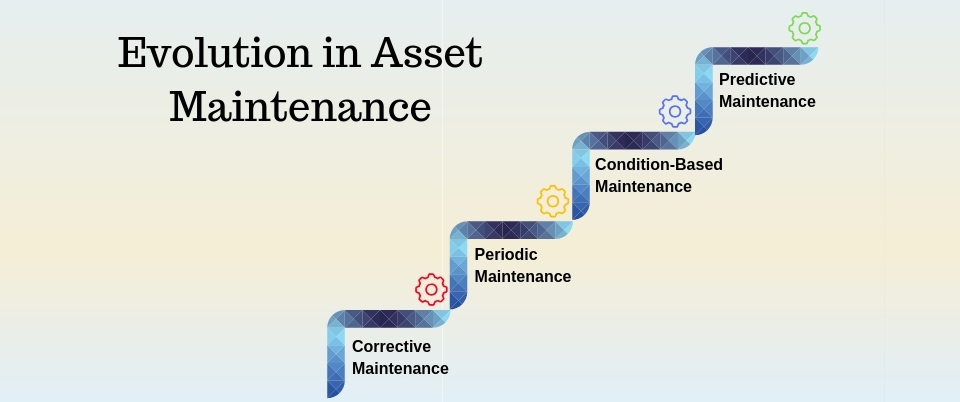

Let us quickly look at the old maintenance methods along with their draw backs

| Old Practice | How it works | Demerits |

| Corrective Maintenance | Assets must operate until they breakdown or equipment malfunctioning | Total equipment replacement and asset downtime affects productivity significantly |

| Periodic Maintenance | Maintenance based on a pre-set time interval whether asset requires maintenance or not. | Increases unnecessary maintenance cost |

| Condition-Based Maintenance | Maintenance should only be performed when certain indicators show signs of decreasing performance or failure. | Causes high installation costs for minor equipment and a greater number of parts need maintenance and checking |

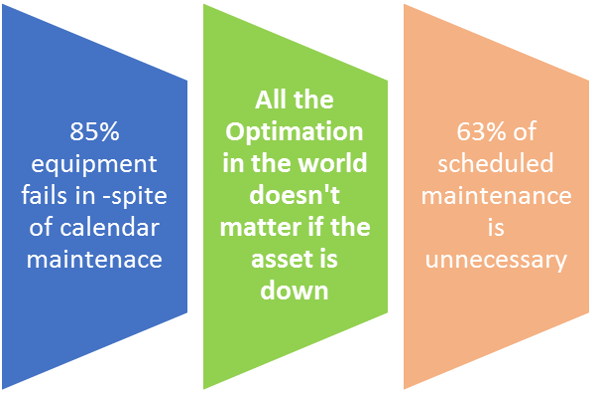

Ground Realities of Maintenance

Let’s look at APM (Asset performance Management)

APM is a holistic system, where Predictive Maintenance is a part.

Asset Performance management (APM) systems act to improve the reliability and availability of physical assets while minimizing risk and operating costs. APM typically includes condition monitoring, predictive maintenance, asset integrity management, reliability-centred maintenance, and often involves technologies such as asset health data collection, visualization, and analytics.

USPs of Predictive Maintenance:

- Reduces maintenance costs

- Reduces machine failures or downtimes

- Increases equipment lifetime

- Improves productivity

- Increases safety, reliability and availability

Why Choosing Predictive Maintenance is a smart step for Industries

Internet of things (IoT), machine learning (ML), cloud computing and big data analytics facilitate industries to move towards Predictive maintenance. Sensors are used in machines (or systems) for data collection, and ML to study the machines continuously. They sense temperature, vibration, conductivity and vital parameters. Any disturbance/deviation from healthy parameters in regular mechanism or in performance, operator is alerted to perform maintenance activities.

Using this data (from sensors and ML that provides analytics), IoT creates “advanced prediction models” and analytical tools to predict failures proactively. Implementing predictive maintenance in industries facilitates increased uptime, therefore greater productivity. Accuracy of ML algorithms improves over time, further reducing maintenance costs and increase return on investments. Choosing Predictive Maintenance is a smart step for Industries.

Where do I find a Solution Provider for me?

Look for a Company that is deep into IoT, ML and data analytics, with experience in providing Predictive Maintenance solutions for large systems, preferably who can also undertake AMC, provide unconditional warranty and maintenance.